How to Fit the Puzzle Pieces Together

Whether the company need is identified as a design or optimization exercise, it remains undeniable that the correct approach to facilities planning is pivotal. Initially, this synthesis might come as an afterthought to the facilities infrastructure and plant facilities system design. However, it’s once the objectives have been realized that the need for an extensive approach is necessitated.

Facilities Layout Planning: Application of SLP for Optimised Configuration

Manufacturing facilities planning may be subdivided into the subjects of facilities location and facilities design. Facilities location addresses how the geographical location supports the objectives with facilities design as an enabler to support achieving the facility’s objectives.

Figure 1: Manufacturing Facilities Planning Components

Incorporating a holistic view into the facilities planning approach will permit the incorporation of elements such as total integration of all company entities, economic progressiveness with the adoption of innovative fiscal practices to aid in decision-making and the consolidation of disparate business entities that result in stronger stakeholder relations.

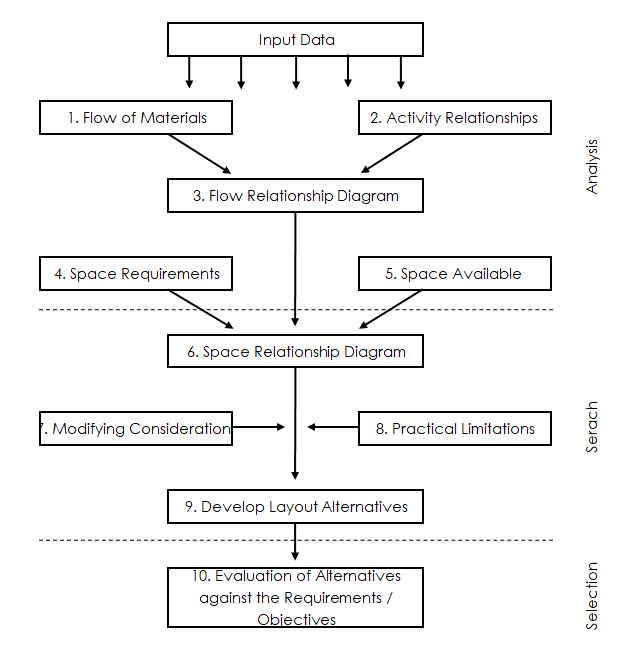

SAIYL typically implements Muther’s Systematic Layout Planning (SLP) Procedure for plant layout configuration as a subdivision of the plant design. This procedure is applied after the manufacturing equipment and material handling equipment selection process. This framework uses as its foundation an activity relationship chart. The creation of this chart is perfected based on the understanding of roles and relationships between activities, material flow analysis and activity relationship analysis.

The figure below illustrates the ten-step procedure with sequential tasks to be performed to ultimately achieve the development of layout alternatives with the incorporation of Lean Manufacturing and Waste Elimination design elements. Each of these steps requires the implementation of custom-designed tools, charts and statistical analysis to elicit the creation of optimized facility layouts.

Figure 2: Muther’s Systematic Layout Planning (SLP) Procedure

Source: Facilities Planning, 4th Edition – Tompkins, White, Bozer and Tanchoco

~ Ugo Louw